5 Easy Facts About 24hr Media Shown

5 Easy Facts About 24hr Media Shown

Blog Article

Examine This Report about 24hr Media

Table of ContentsSome Known Incorrect Statements About 24hr Media Some Ideas on 24hr Media You Should Know8 Simple Techniques For 24hr MediaGetting The 24hr Media To WorkThe Best Strategy To Use For 24hr Media

Improvements in print modern technology are transforming the interactions playing area when it involves high quality, affordability and sophisticated capacities. Balanced out printing and electronic printing are the significant processes by which print jobs are embarked on both using four-color printing methods. Each option has its advantages, supplying various techniques to satisfy the needs of varied production jobs.

Typically, this has been the most constant method for exactly preserving shade suits, making it excellent for print runs that just need fixed printing such as pre-printed types, pamphlets, flyers, organization cards, and mass postcard mailings. Nevertheless, as a result of the fixed nature of litho printing, it is not ideal for variable print items that will certainly be mailed to specific receivers such as statements, letters, and customized postcards.

Some Known Questions About 24hr Media.

The current innovations in print innovation are aiding to bring numerous of offset's advantages right into the digital printing world absolutely changing the face of modern printing! There are some crucial distinctions between Offset Printing and Digital Printing (Signage). This overview shows the advantages and downsides of each printing technique. There is an obvious and growing number of advantages to utilizing the electronic print procedure.

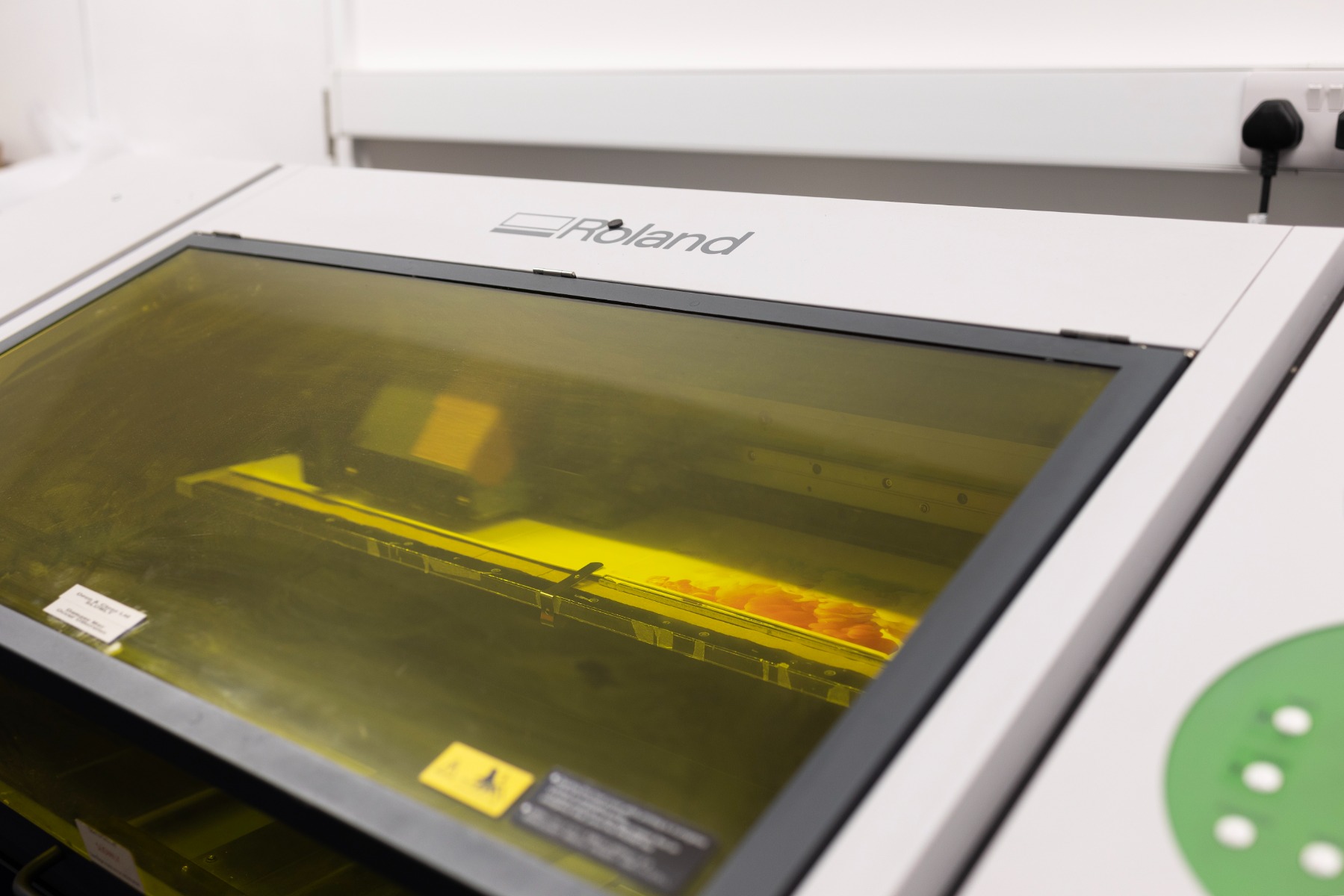

Today's electronic print equipment is among the most innovative on the marketplace. Below are a few of the greatest advantages of using digital printing: control the digital print area, with full-color printing finished in one process and perfectly printed directly from a print data. Without an extensive set up procedure, the calibration time of a specific task is shortened, contributing to quicker print time and general distribution.

The inkjet printing procedure has assisted to change the sector along with the top quality and rate of the output. The newest inkjet technology can publish on typical balanced out stocks with plain, silk, and shiny surfaces. Top notch digital print coupled with software-managed shade monitoring methods includes optimum value to publish pieces and makes production procedures a lot more reliable than offset.

Getting The 24hr Media To Work

(https://hearthis.at/fred-mack-mn/set/JGlI4/)

Green and biodegradable inks and printer toners are likewise readily available for even more sustainable printing. Digital print also gets rid of the demand to wash plates or blankets with unsafe chemicals at the end of the printing procedure.

Variable information assists businesses reach their exact customers and target market with uniquely-created and individualized web content. As innovation enhances, the quality of electronic printing has come to be second-to-none, with higher detail, shade suit capabilities and total precision. Without the demand to clean plates or use excess ink, electronic printing is also less inefficient and typically extra eco-friendly.

Traditional printing approaches, such as offset lithography ("countered") and flexography ("flexo"), entail multiple make-ready actions to move an initial image to a substratum. These methods require the production of a series of plates placed on a cylinder to transfer ink that creates the desired picture when incorporated on paperboard and other product packaging products. Custom Printed Packaging.

Some Known Details About 24hr Media

While electronic printing is a viable alternative for many short-run print tasksspecial occasions, prototyping, or various other considerationsits contemporary capacities actually display in rapid turn-arounds. Having the ability to tailor product packaging with variable information printing has opened up new chances for you to involve with your consumers in more customized methods. Digital printing, with fewer moving items, is a lot more active than balanced out hereof.

It's a method to mix your product packaging and advertising and marketing approaches. Minimized set-up time saves cash on the front end. And considering that these are not large mass orders, smaller companies can afford to publish without needing to satisfy the higher and extra pricey print limits of conventional printing. Digital printing helps safeguard your brand against counterfeiting by including obvious and concealed options on your product packaging.

Make sure you collaborate with a printing and product packaging partner who has the right qualifications. While eleventh-hour printing and personalization are a substantial benefit, electronic may not always be the finest method for you. For instance, counter printing has the benefit of cost-effectiveness with large print runs, specifically those with sophisticated attractive impacts and specialized finishes.

The smart Trick of 24hr Media That Nobody is Talking About

The positive plate, with its smooth surface area, draws in oil-based inks and fends off water. In comparison, the unfavorable plate, with its rough appearance, absorbs water and drives away oil. Rubber rollers are then used to move the image from the plate to the corrugated surface.

Corrugated paper can occasionally confirm to be a challenging surface area to print on, however Litho prints to a different surface and is after that laminated flooring to it, making it easy to publish premium photos. It can be very regular, even for futures. As a matter of fact, the more you print, the less costly the costs come to be why not try this out for Litho.

If you have enough time and budget plan, and a huge volume of a solitary style, after that there should not be a concern. What Litho doesn't offer you is exactly what Digital does, personalization. Extra on that later on. Pricey established up Longer turnaround No Variable Information Printing Smaller sized shade range, colors can be less bright Digital printing is the process of printing digital images directly onto the corrugated substratum utilizing a single-pass, direct-to-corrugate method - Custom Boxes.

Report this page